ARCOSYSTEM® Size 1 and 2

Elevated GRP Cable Duct

Whether on rail routes, at airports, or in the field of energy supply, the availability of modern systems largely depends on reliable power supply and transmission of information. In this context it is important that a multitude of sensitive cables are efficiently protected against outside influences. The elevated GRP cable duct system offers reliable protection against foreign influences and was designed for difficult terrains. The elevated GRP cable duct system ARCOSYSTEM® Sizes 1 + 2 was designed for topographically difficult terrains along the rails. Even in such conditions the laying of cables does not present a problem. ARCOSYSTEM® Size 1 has a usable inner cross section of 100 x 150 mm and ARCOSYSTEM® Size 2 250 x 150 mm. The elevated cable duct ARCOSYSTEM® Sizes 1 + 2 allows a maximum distance of 6 metres between the sigma posts. Therefore a structural analysis was done and rechecked by an inspecting structural engineer. The GRP cable duct is extremely light, yet solid due to the double-walled construction of the base. The lid snaps in to the base and can only be opened with an accurate tool.

Easy to install

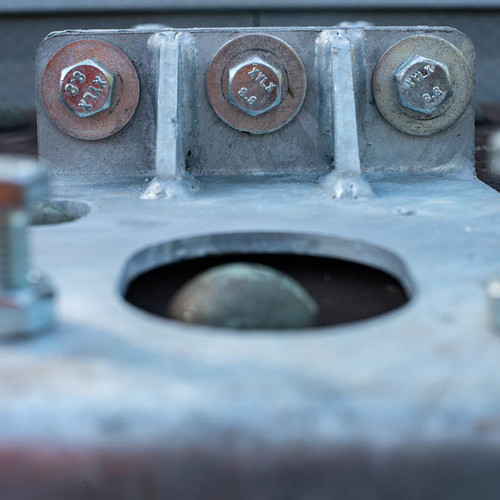

Connection plate, sigma post and the GRP cable duct base and lid are extremely easy to install. The sigma post is rammed into the soil. Then, the connection plate is bolted together with the sigma post. Depending on the selected fixation with 2 or 4 bolts, the 6 metre long GRP cable duct base is inserted into the fixation. The 6 metre long GRP lid snaps in the GRP cable duct base without any additional fixings.

Benefits

As a result of this easy to install system the assembly time of the cable duct is extremely reduced. The simple and thus fast installation provides a great advantage. Overall, the GRP cable duct system presents a commercially viable alternative to conventional concrete cable ducts. Thanks to this solution, the project duration is shortened and the construction and labour costs are low.

- easy to install

- snap-on lid

- standard span of 6 metres

- low cost of transportation, simple handling

- solid design, made of glass-fibre-reinforced (GRP)

- non-conductive, no earthing required

- high mechanical stability

Material

Polyesterresin with glassfibre fabrics and glassfibre rovings. Surface veil on outer surface.

Mechanical Data

The elevated cable duct system is designed to withstand a working load of 0.45 kN/m for ARCOSYSTEM SIZE 1 and 0.9 kN/m for ARCOSYSTEM® SIZE 2, additionally in the middle of the duct a man load of 0.75 kN and a horizontal load from wind pressure of 1.45 kN/m2.

Electrical Values

Earthing and insulated construction are not necessary. Breakdown voltage according to

DIN EN IEC 60243-2 25 kV.

Thermal properties values

Permanent dimensional stability between -30 °C and 80 °C. UV-resistant.

Fire behaviour

K 1/3 mm in accordance with DIN 53438 part 2 V0 in accordance with UL 94 S4 in accordance with DIN 5510-2 Halogenfree in accordance with IEC 61249-2-21

Weight

ARCOSYSTEM® SIZE 1 approx. 5 kg/metre duct and lid ARCOSYSTEM® SIZE 2 approx. 7.5 kg/metre duct and lid

The alternative

Elevated cable duct ARCOSYSTEM® Size 1 + Size 2

Plastic cable ducts made of glassfibre reinforced composite or polypropylene are considered to be an economical alternative to conventional concrete cable ducts and are increasingly used in cable route construction by railways for the provision of communications and power supplies. In addition to shortening the duration of projects, they also help to lower mobilization, installation and labour costs. The elevated GRP cable duct is based on a multichamber system and additional glass fibre reinforcement in the form of glass fibre multiaxial fabrics. The reinforcement geometry and the multi-chamber design provides significantly higher strength in the transverse direction. The system is designed such that it floats freely in the mounting heads (rigid or swivelling heads) until fixed. Once the ideal fixing position is established the GRP trough is fixed firmly within the mounting head using clamping bolts that spread the load of the mounting head on the GRP trough. Bending tests performed during development showed that the multi-chamber system used in conjunction with glass fibre multiaxial fabrics is a superior design compared to other systems. Thanks to the inclined side walls, it was possible to design the mounting head such that the GRP cable duct trough can be mounted using a floating arrangement. float mounting makes straightforward insertion into the mounting head is an important step with regard to simplified installation. Efforts were also intensified to develop a screw-free, snap-in cover, which helps to further shorten installation times. The elevated GRP cable duct ARCOSYSTEM® Size 1 + Size 2 is very easy to install. The elevated GRP cable ducts ARCOSYSTEM® were developed for tracks that pass through topologically difficult terrain and offers reliable protection against the elements. Cables can be laid without problems even under the most difficult conditions. ARCOSYSTEM® Size 1 has a usable cross section of 100 x 150 mm, while that of ARCOSYSTEM® Size 2 is 250 mm x 150 mm. The elevated GRP cable duct ARCOSYSTEM® is designed for a maximum span of 6 meters between 2 sigma-section posts. ARCOSYSTEM® Size 1 + Size 2 - made of glass fibre rein-forced plastic - is extremely light, yet very stable, thanks to its double-walled construction. The cover is fitted by simply snapping it into the cable duct, and it can be opened using a suitable tool. The design capability of ARCOSYSTEM® Size 1 + Size is known and documented. Its successful use is ensured by continued use within its design limits and where public safety and order are not endangered. The minimum distance to the track centre depends on the line speed and must be determined in accordance with the currently applicable train guidelines. A thorough assessment must be performed before using the ARCOSYSTEM® Size 1 + Size 2 in areas prone to snow slides and snow drifting (e.g. in Alpine regions, in cuttings through terrain and on embankments), especially in snow load zone III, or in areas in which there is a risk of falling rocks.